Overview

My guitars are different

And not only in their choice of material. I made it my mission to rethink every part and feature from the ground up, utilizing the much greater precision metals allow for — creating guitars that not only catch your attention, but also keep it.

Please explore my creations: my heart and soul can be found in them.

And not only in their choice of material. I made it my mission to rethink every part and feature from the ground up, utilizing the much greater precision metals allow for — creating guitars that not only catch your attention, but also keep it.

Please explore my creations: my heart and soul can be found in them.

Models

Two shapes, one feature set

My “Racer” and “Aviator” models share the same core construction principles and hardware philosophy. Both shapes offer sleek curves — rarely seen on an aluminum guitar.

Both guitars are available as headed or headless versions, with either a fixed bridge or a vibrato.

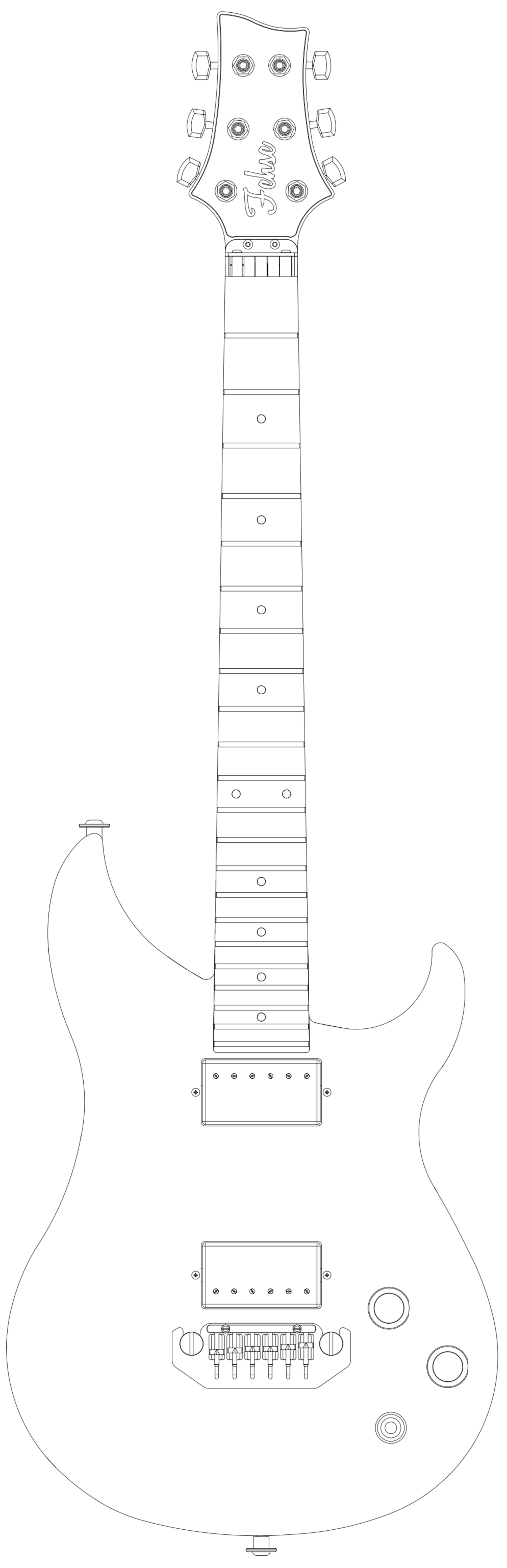

Racer

A nod to the legendary asymmetrical double-cut design we all know and love. The Racer, however, is smaller and thinner. Its curves are reminiscent of a supercar — hence the name. Forget clunky and enter the world of a lightweight (7 lbs) high-performance aluminum guitar with incredible upper-fret access.

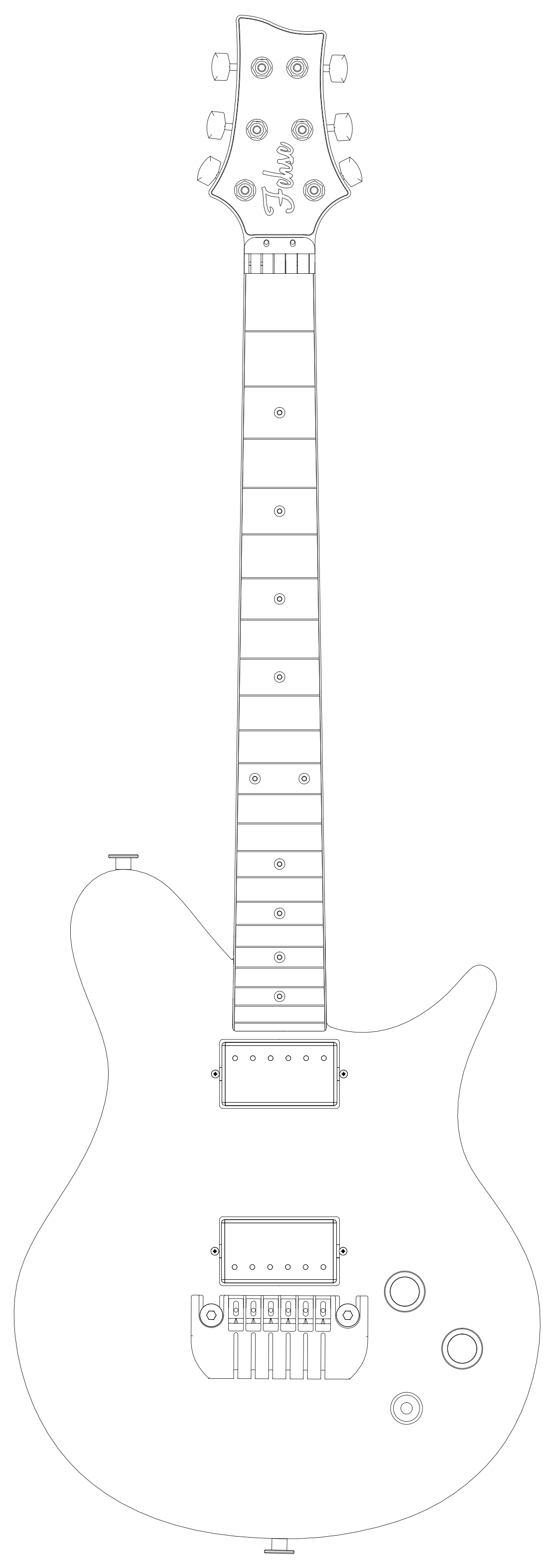

Aviator

This model arose out of my very first prototypes, and with each iteration it became a little more ergonomic and a little more unique in its appearance. While it is by no means a radical departure design-wise, it’s just different enough to free you from the baggage that comes with a classic shape, allowing you to transcend the same old ideas and licks and reach new creative heights, like an aviator.

My “Racer” and “Aviator” models share the same core construction principles and hardware philosophy. Both shapes offer sleek curves — rarely seen on an aluminum guitar.

Both guitars are available as headed or headless versions, with either a fixed bridge or a vibrato.

Racer

A nod to the legendary asymmetrical double-cut design we all know and love. The Racer, however, is smaller and thinner. Its curves are reminiscent of a supercar — hence the name. Forget clunky and enter the world of a lightweight (7 lbs) high-performance aluminum guitar with incredible upper-fret access.

Aviator

This model arose out of my very first prototypes, and with each iteration it became a little more ergonomic and a little more unique in its appearance. While it is by no means a radical departure design-wise, it’s just different enough to free you from the baggage that comes with a classic shape, allowing you to transcend the same old ideas and licks and reach new creative heights, like an aviator.

Materials

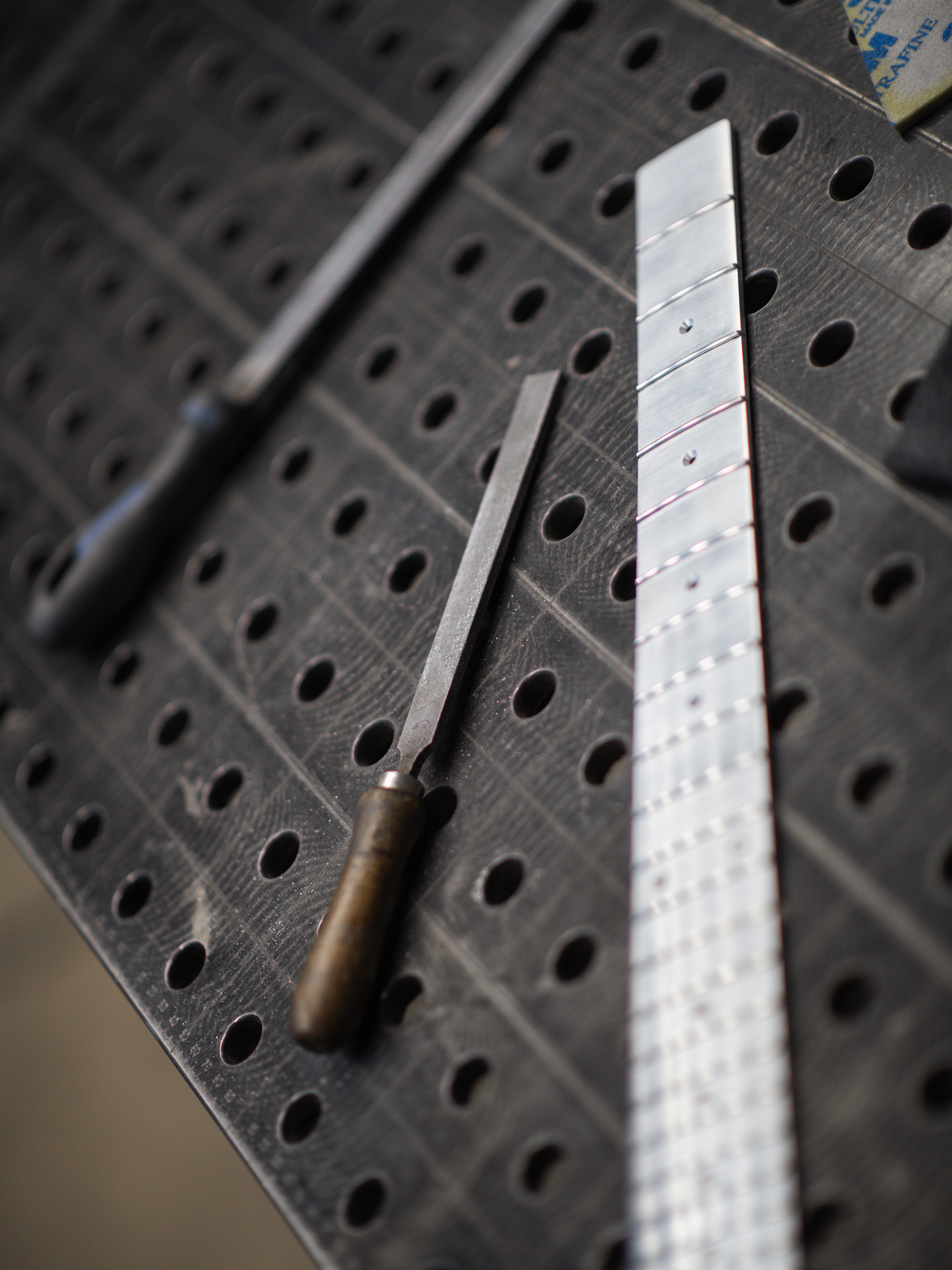

Working with aluminum doesn’t just allow tolerances in the range of tenths and hundredths of a millimeter — it demands them

A single flaw, a millimeter more or less, and a part is often unusable. That’s why every choice is made with an engineer’s mindset, from construction to materials. Aluminum, brass, stainless steel, and steel are chosen for stability, precision, and longevity. CNC delivers the accuracy — the final feel comes from handwork: edges, sanding, and finish.

Precise calculations are of vital importance, but the last few percent only come with empirical testing and iteration. This laborious process resulted in my hollow neck design: lighter in weight, and more stable in real-world temperature swings. The air volume inside acts as a buffer, helping the neck adapt faster and more predictably.

And it enabled something even more important: near-perfect relief and extremely low action without a truss rod. A PLEK® measurement showed that, at its “worst” point, my neck deviates by just 0.1 mm from the perfect curvature — and that result is consistently reproducible across my guitars. No luck involved, no risk of a “dud”. Said measurement was taken at NAMM, where humidity is so low that even premium wooden guitars may crack — something Fehse owners will never have to worry about.

A single flaw, a millimeter more or less, and a part is often unusable. That’s why every choice is made with an engineer’s mindset, from construction to materials. Aluminum, brass, stainless steel, and steel are chosen for stability, precision, and longevity. CNC delivers the accuracy — the final feel comes from handwork: edges, sanding, and finish.

Precise calculations are of vital importance, but the last few percent only come with empirical testing and iteration. This laborious process resulted in my hollow neck design: lighter in weight, and more stable in real-world temperature swings. The air volume inside acts as a buffer, helping the neck adapt faster and more predictably.

And it enabled something even more important: near-perfect relief and extremely low action without a truss rod. A PLEK® measurement showed that, at its “worst” point, my neck deviates by just 0.1 mm from the perfect curvature — and that result is consistently reproducible across my guitars. No luck involved, no risk of a “dud”. Said measurement was taken at NAMM, where humidity is so low that even premium wooden guitars may crack — something Fehse owners will never have to worry about.

Neck

Fretboard

Nut

Body

Bridge

Details

Features

The features are what truly set my guitars apart

I didn’t want to make a guitar that’s different but unsuited for live playing or long sessions. Neck dive was out of the question. And exceptional playability was a must. So I set out to find creative solutions to each of those challenges.

The result is a guitar that’s genuinely unique in almost every aspect — although at first glance it might not seem like a radical departure. That’s because I don’t do things differently just to be different, but only where it truly makes sense and actually constitutes an improvement.

Click on the features to learn more — it’ll take you about 5 minutes to read what took me 15 years to create.

I didn’t want to make a guitar that’s different but unsuited for live playing or long sessions. Neck dive was out of the question. And exceptional playability was a must. So I set out to find creative solutions to each of those challenges.

The result is a guitar that’s genuinely unique in almost every aspect — although at first glance it might not seem like a radical departure. That’s because I don’t do things differently just to be different, but only where it truly makes sense and actually constitutes an improvement.

Click on the features to learn more — it’ll take you about 5 minutes to read what took me 15 years to create.

Finishes

Aluminum offers amazing possibilities for applying color

Anodizing, blasting, brushing — finishes can be shiny and bold, ultra-clean, or industrial. Most of my finishing types, e.g. powder coating, are far more durable than lacquer finishes on wood. And when they do get dinged up over time, they develop a unique kind of “industrial aged” look.

The finishing techniques not only differ in appearance, but also in feel. Browse the gallery to see how different the surfaces can look.

Anodizing, blasting, brushing — finishes can be shiny and bold, ultra-clean, or industrial. Most of my finishing types, e.g. powder coating, are far more durable than lacquer finishes on wood. And when they do get dinged up over time, they develop a unique kind of “industrial aged” look.

The finishing techniques not only differ in appearance, but also in feel. Browse the gallery to see how different the surfaces can look.